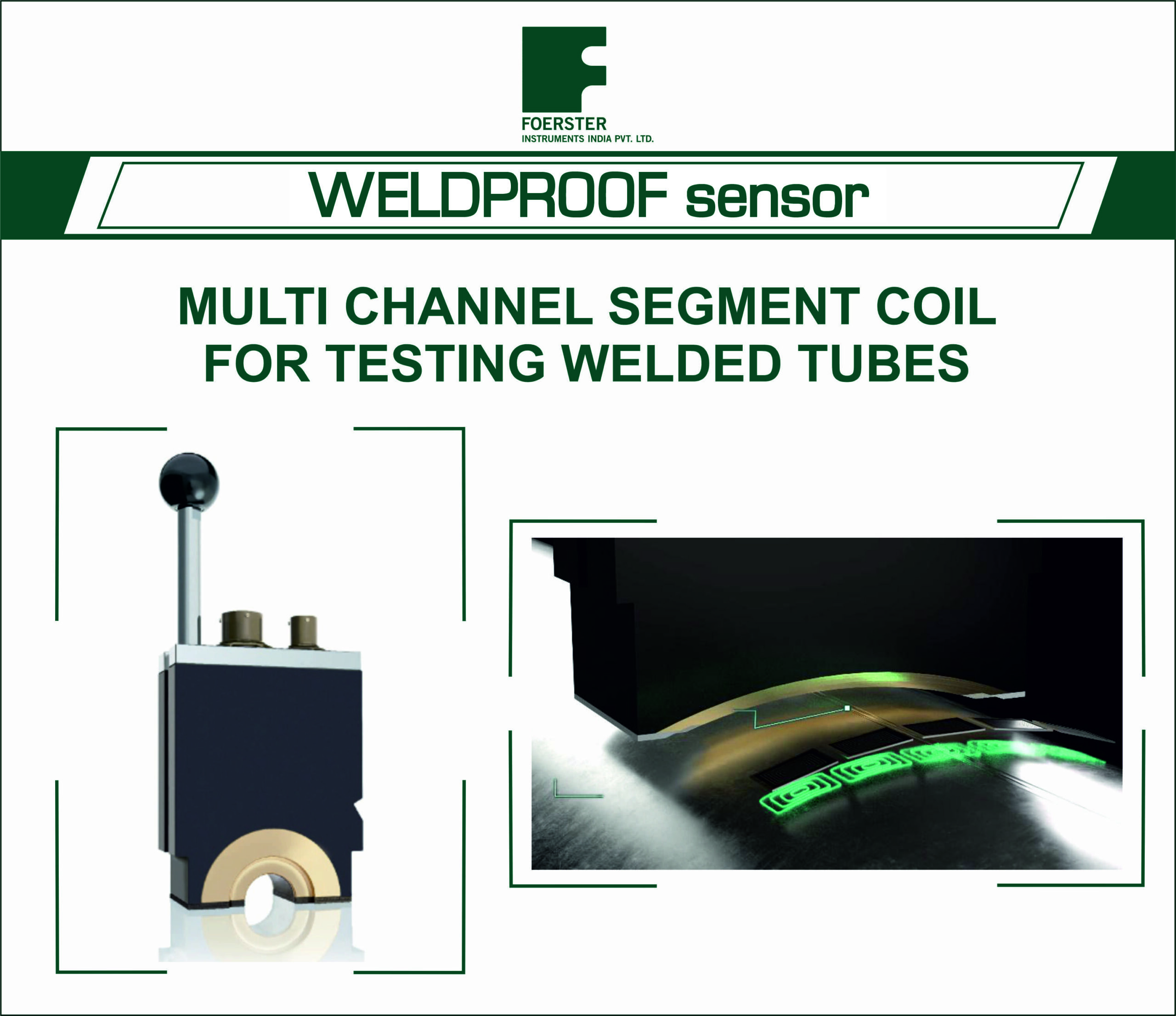

MULTI CHANNEL SEGMENT COIL FOR TESTING WELDED TUBES

Weld seam testing with clearance compensation

FOERSTER has developed the new WELDPROOF sensor with dynamic clearance compensation to monitor the weld seam quality. This also enables you to inspect eccentrically guided tubes with high reproducibility. As the sensor covers a large area, possible to inspect migrating welds while maintaining a consistently high inspection quality. Additionally, an absolute channel monitors the welding process and immediately detects unwelded zones.

It has 5 test channels and 5 clearance channel which makes detection of small defects on large diameter tubes also very reliable. The exact defect location obtained from Weldproof helps in making valuable conclusion about the manufacturing process.

The Benefits

- Significantly higher reproducibility of test results due to innovative clearance compensation. This automatically leads to higher output of inspected material.

- Higher sensitivity compared to conventional segment coils enables reliable detection of the smallest defects on tubes with larger diameters (improved interaction volume).

- Exact defect locations, specified in both longitudinal and circumferential position.

- Additional integrated absolute channel for control of the welding process.

- Compatible with all existing mounts and magnetizing yokes from FOERSTER.

- Available in two sizes: Size I (nominal diameter 17-44 mm), II (nominal diameter 47-500 mm).

For more details, please get in touch with our Sales Team.