Industry: Oil and gas

Material/Part type: Drill collar

Measuring parameter: Magnetic field

Industry standard: API Spec 7

FOERSTER device: MAGNETOSCOP/MAGNETOMAT with Differential Probe

Precise drill-direction monitoring is one of the main tasks in modern deep-bore technology. To guarantee guidance of the drill-bit towards the oilfield to be developed the compass-like navigation unit must not be influenced by magnetic anomalies generated by the drilling pipe. Only in this way deep-bore sites can be operated economically, safely and optimized technically in confined target areas today.

Drill collar is a component of a drilling unit (drill-string) providing weight on bit (rock crushing and cutting tool) and usually made of austenitic steels or other non-magnetic alloys. In the directional drilling non-magnetic properties are required to limit a magnetic influence of the drill collar on the navigation compass being also a part of the drill-string. However, due to various reasons, e.g. caused by milling, mechanical or heat treatment, adherence from transport or storage, drill collar material could change its magnetic properties. For that reason drill collars are subject to precise measurements for magnetic or so-called “HotSpots”. Particularly, API Spec 7 is a norm that describes such measurement and limits (+/-0.05 µT deviation from a constant magnetic field), confirming low magnetic property of the underlying material.

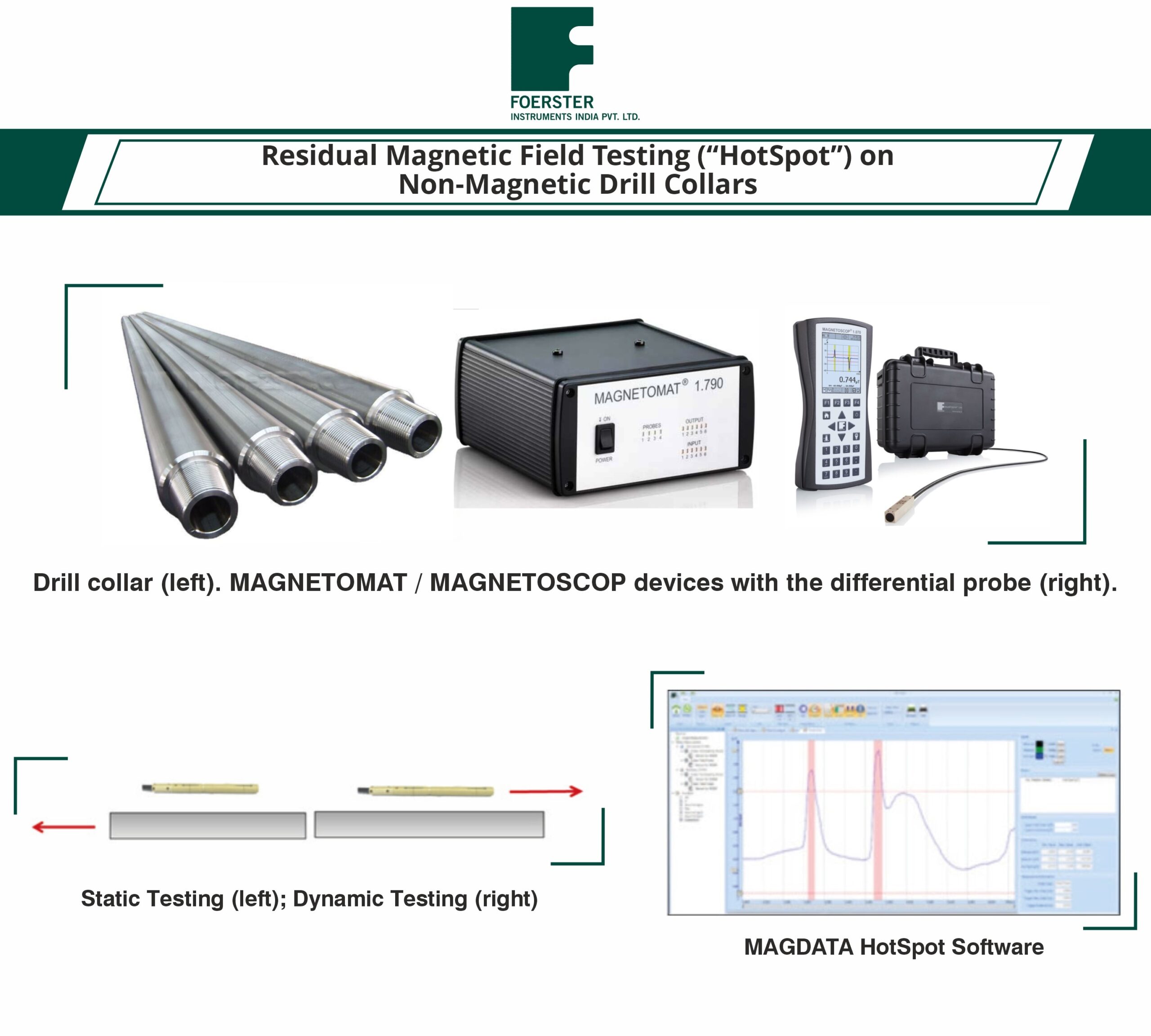

With FOERTER’s MAGNETOSCOP (portable device) or MAGNETOMAT (stationary device) and with the differential probe, such measurement could be conducted using two approaches:

- The probe is static and the drill collar moves.

- The drill collar is static and the probe moves.

Additionally to the above application set, in order to comply with API Spec 7 for a constant magnetic field, further specific environmental conditions must be adhered to by all procedures implemented at the measurement site, e.g. ferromagnetic masses located close to the measurement site must not be moved during the measurement, field generating components such as motors, transformers and the like must be switched off during the measurement.

After measurement, the data could be further handled using FOERSTER’s MAGDATA HotSpot software, enabling data selection and reduction, visualization of measuring data, definition and display of threshold values, highlighting of magnetic anomalies and API Spec 7 report generation.

For testing of magnetic anomalies on drill collars we recommend FOERSTER’s MAGNETOSCOP or MAGNETOMAT device with Differential Probe.

For more information and demonstrations, please get in touch with our Sales Team.