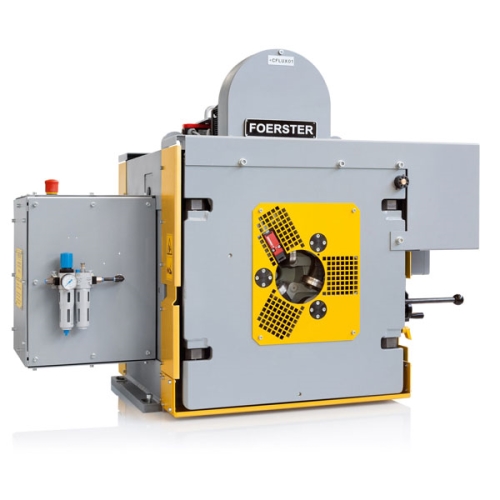

Effectiveness meets highest precision

Precision is our strength, as the CIRCOFLUX sensor systems with rotating probes reliably detect small surface defects of 0.1 mm or greater. Due to the alternating field magnetization, an additional demagnetization is not necessary. The four available sensor systems cover a material diameter of approx. 10-180 mm. This makes them suitable for a wide range of test tasks and ensure maximum effectiveness of AC flux leakage testing with throughput speeds of up to 4 m/s.

Your advantages at a glance:

- Maximum detection sensitivity of defects from 0.1 mm depth on ferromagnetic rods with hot-rolled surface

- Test material diameter from 10 – 180 mm

- Pivoting test levers also tolerate non-straight material and protect against damage to or destruction of the test elements

- Central adjustment to the test diameter minimizes the risk of adjustment errors

- Automatic dimensions adjustment reduces setting up time and increases productivity