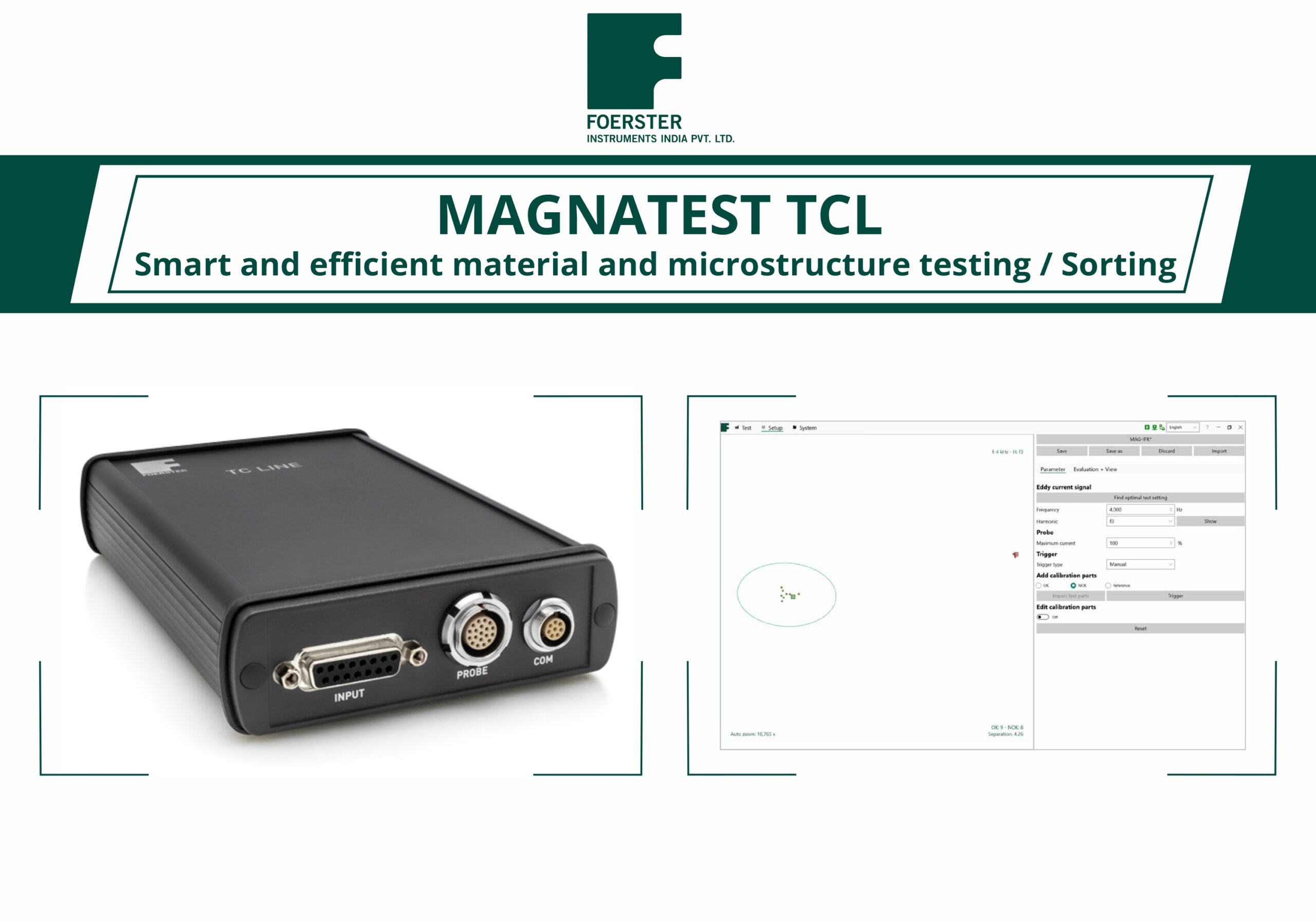

The MAGNATEST TCL is designed for fully automated and non-destructive eddy current testing for 100% inspection in series production. In addition, it can be used for manual testing, e.g. in a laboratory for quality assurance. The MAGNATEST TCL testing system consists of the Test Channel Line (TCL) and a PC with testing software.

Benefits :

- Magneto-inductive testing with fundamental and harmonic evaluation

- 100% control using non-destructive testing method

- State-of-the-art software with intuitive user interface

- Improved test quality

- Innovative probe recognition

- Easy automation and line integration

Applications :

- Material mix-up testing

- Alloy composition testing, inhomogeneity testing

- Microstructure testing: e.g. austenite, ferrite, pearlite, cementite, ledeburite, dendrites, etc.

- Testing of different heat-treatment states: hardening, quenching and tempering and annealing

- Hardness and strength testing (Young’s modulus)

- Testing of case hardening and case hardening depths

- Monitoring of geometrical properties: form fidelity, machining condition

- Testing of coatings and surface treatments

Robust sensors for precise results :

You can choose from a wide range of sensors for different shapes and diameters. Depending on the inspection task and complexity of the components, we also develop application-specific sensor technology for you.

To Automate your NDT Inspection & to get more information, please get in touch with our Sales Team.