EDDYCHEK 6

The EDDYCHEK 6 series is an Eddy current testing equipment made by PRUFTECHNIK (now a part of the FOERSTER Group) used for non-destructive material testing A reliable and economical testing solution for a high speed testing using encircling coils and segment coils. It complies with various international norms like ASTM, API, BS, JIS, ETTC, ENEL, DIN, and SEP.

Key Features:

- Multichannel, Multifrequency Testing: Supports up to 10 channels at up to 6 testing positions, allowing for combinations differential, absolute and FERROCHEK channels.Wide

- Frequency Range: Offers 175 discrete test frequencies from 100 Hz to 1 MHz.

- Advanced Filtering: Features high-pass and low-pass filters and Optional speed related adjustments

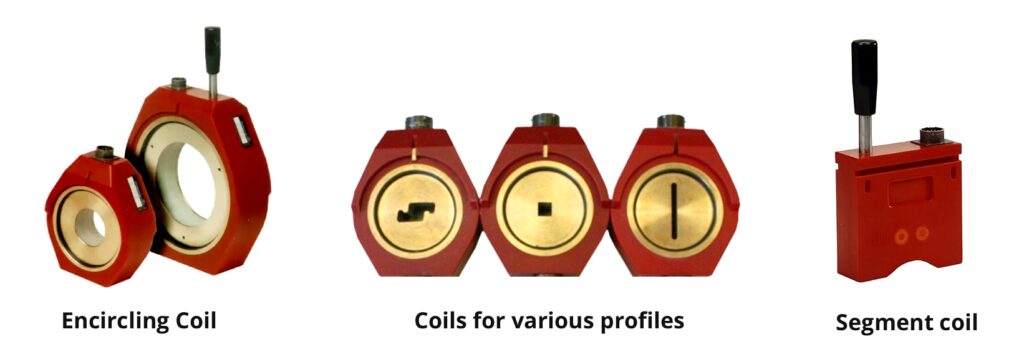

- Coil Monitoring: Monitors transmitter and receiver coils, with automatic reading of coil information when using Smart Sensors.

- Comprehensive Test Result Documentation: Compiles results on two levels (per order and part/batch/shift) and can save order-related results as XML files. Optional interface to a SQL database for storing line and test parameters, and results.

- User-Friendly Interface: Features a multitasking RTOS, touchscreen operation with icons, archiving of testing parameters, and a graphical user interface with context-sensitive help in local languages. Includes a password-protected supervisor level.

- High Speed Capabilities: Can handle continuous production up to 20 m/s for inline testing and up to 250 m/s for wire testing. For offline testing of cut lengths, it can process up to 10 pieces per second.

- Speed Measurement: Integrated speed measurement with encoder (up to 40 kHz) or light barrier.

Applications:

The EDDYCHEK 6 series is broadly used in the production and quality assurance of semi-finished products and other conductive materials.

- Common applications include:

- Final testing and quality assurance:

- Tubes, pipe, bar, wire

- Strip, cable sheathing, extruded sections (e.g., from roll forming, tube mills, drawing machines)

- Process control: Such as cut lengths and coil-to-coil production.

- Testing of various conductive materials: Nonferrous metals, ferrous metals (ferritic, austenitic, duplex).

- Common defect detection: Surface Cracks, Ferrous inclusions, pitting and discontinuity in welds

- Industries: Automotive, aerospace, power generation (e.g., heat exchanger tubes, turbine blades), oil and gas (pipelines), and general manufacturing.

To automate your NDT inspection & to get more information, please get in touch with our Sales Team.