In the demanding copper industry, maintaining product quality, surface integrity, and material consistency is non-negotiable. From wires to tubes, customers expect zero defects and maximum conductivity.

FOERSTER Instruments India (FIIND) offers a range of precision Eddy Current testing solutions that enable non-destructive at high-speeds, and highly reliable inspection for copper-based products – right on the production line as well as manual testing.

Here’s how our Eddy current testing solutions ensures your copper products meet the highest standards.

Surface Crack & Defect Detection on Copper Wires, Bars & Pipes

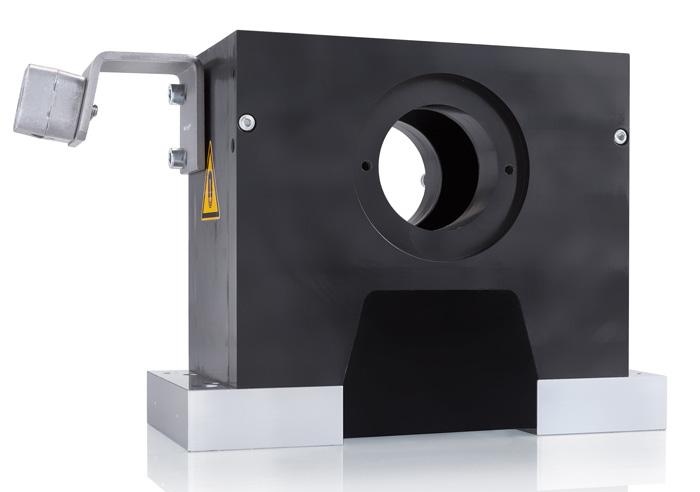

Designed for longitudinal and transverse surface defect detection, various options for the electronics from the CIRCOGRAPH and DEFECTOMAT families provide reliable, real-time inspection of semi-finished copper products.

The system’s robust design and customizable sensor systems allow seamless integration into your production workflow.

Highlights:

● High Speed Testing

● Simple integration into existing lines

● Easy integration with paint marking system and/or audio visual alarm.

● Outputs can be integrated to the existing PLC for customization

Sensor System P – Detection of Ferrous Inclusions in Copper

Even the slightest ferrous inclusion can compromise copper’s quality and performance. The Sensor System P, when combined with the FERROMAT channel, detects ferrous contaminants in copper rods and tubes – with precision and efficiency.

Features:

● Suitable for diameters from 1 mm to 40 mm

● Capable of detecting pinhole and transverse defects

● Supports encircling coils,

● Compliant with DIN EN ISO 15549 standards

SIGMATEST – Conductivity Measurement of Copper

Electrical conductivity is one of copper’s most critical properties. The SIGMATEST 2.070 offers fast, precise, and portable measurement of conductivity in non-ferromagnetic metals, ensuring your materials meet both internal and customer specifications.

Benefits:

● Automatic compensation for temperature, distance, and curvature

● Frequency range up to 480 kHz with ±0.5% accuracy

● Rugged design for use in production and field environments

● Long-lasting titanium-coated probes

SONODUR 3 – Portable Hardness Testing of Copper Components

The SONODUR 3 provides reliable hardness measurement using both UCI and Leeb methods, making it ideal for post-treatment testing, weld evaluation, and mobile field work. For copper we have special motorized probes for better control.

Advantages:

● Android-based interface for intuitive operation

● Wireless connectivity with Leeb sensors via Bluetooth

● Broadest UCI probe range in the market

● Excellent for confined spaces and hard-to-reach areas

● Built for heavy-duty, daily industrial use

To automate your NDT inspection & to get more information, please get in touch with our Sales Team.