During the production of long products such as bars, wires & tubes, eddy current testing has become a standard for continuous quality assurance. The Circograph family of products from Institut Dr. Foerster GmBH & Co. KG (Germany) provides an advanced solution to accomplish efficient and reliable Eddy Current inspection.

To identify longitudinal defects, sensors in a rotary head move around the test subject at a high speed in a non-contact manner. These helical scans identify longitudinal defects along the length of the material. Due to the small dimensions of the sensors, a very high sensitivity can be achieved .

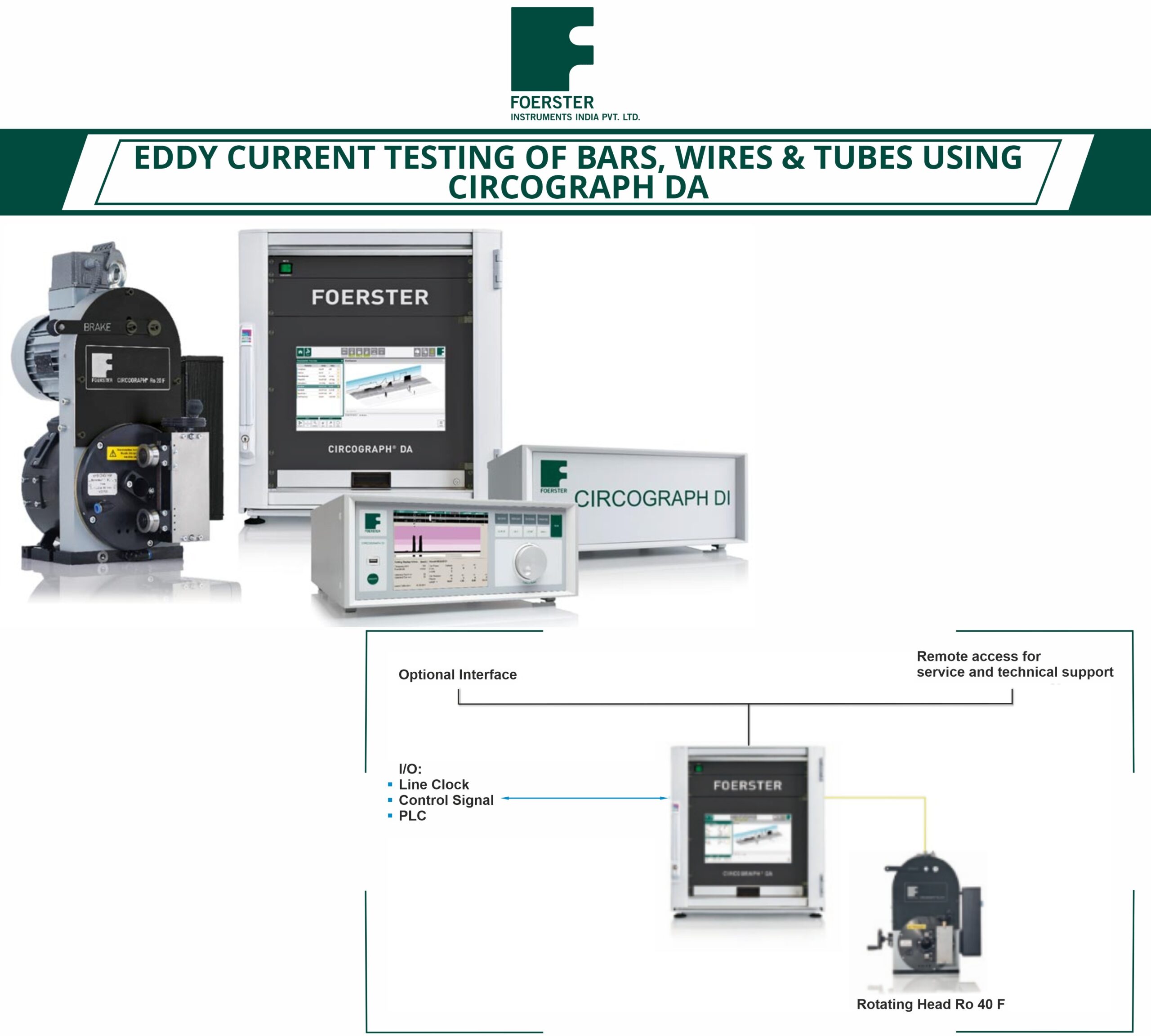

Additionally, the electronics can be interfaced with encircling coils and segment coils to identify transverse and hole-like defects on the surface of the material.

The CIRCOGRAPH DA sets new standards in non-destructive eddy current testing of long products such as tubes, bars and wires. CIRCOGRAPH DA offers unsurpassed reproducibility at high test speeds by combining advanced digital electronics with sophisticated system architecture. It’s modular system setup and the resultant expansion possibilities guarantee maximum versatility for fulfilling ever-changing test requirements.

In order to reduce possible interferences from the outside, the signal paths of the analog test signals have been reduced to a minimum as the digitalization takes place right after the sensor. System modules are connected with industrial Ethernet cables which can be flexibly arranged. I/O interfaces to the production line can be freely configured and expanded. The CIRCOGRAPH DA can be interfaced with upto 256 channels as well as a DEFECTOMAT channel for detecting flaws in all orientations. It’s ability to work over a wide range of frequencies and sensors make it versatile to be adopted into any production line.

The Ro series of rotating sensors are proven solutions for detecting flaws at a high throughput production line. It’s multiple-channel sensor heads can be used for jobs having diameters up to 130 mm. Due to the high RPM and superior sensitivity, material can be tested at speed as high as 6 m/s for flaws as small as 30 µm.

The electronics and sensors are seamlessly integrated into EECI‘s job handling solution. This enables smooth & efficient testing of the production material along with the possibility of customization in automation and other features. Further, after sales support such as AMCs from EECI, ensures the best performance and longevity of the system.

For more information & demo, please reach out to our sales team.