Srews, nuts, fittings or springs – everyone of us has already used these small parts.They can be found everywhere, and yet we rarely think about the constantly high loads to which these components are subjected. Failure can result in exorbitant costs or, even worse, danger to human life. For this reason, ever higher quality requirements are being placed on all types of fasteners. To meet increasing quality demands, Eddy Current Sorter Machines are crucial in ensuring only the highest quality fasteners are produced by accurately sorting materials and detecting defects. This technology helps maintain safety and reliability in fastener production.

To ensure that these tiny elements cause no major disturbances, potential material defects must be detected in time. Only then can countermeasures in the production process be undertaken and defective parts promptly rejected.

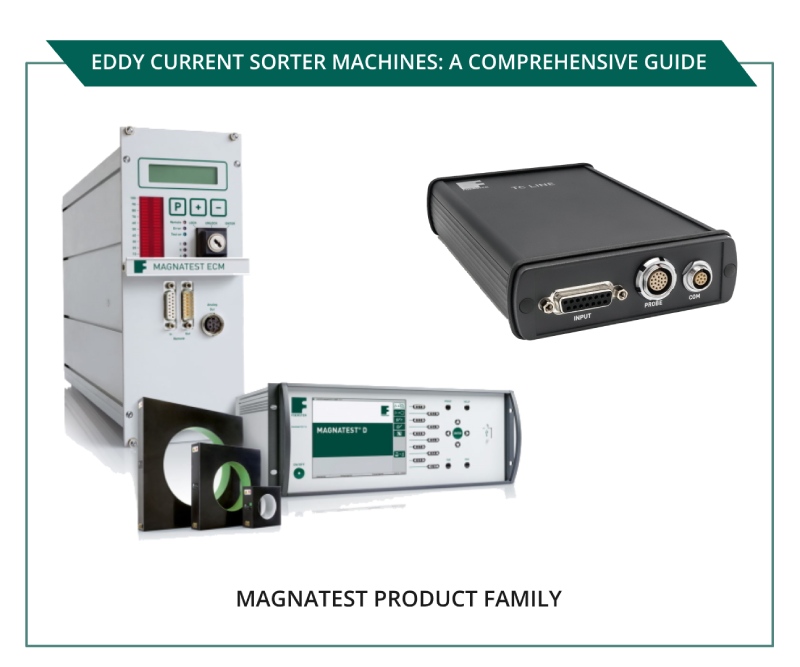

In this comprehensive guide, we will explore how Eddy Current Sorting Systems work, their benefits, applications, and the role of Automatic Eddy Current Sorter Machines in enhancing material sorting. We’ll also highlight innovative machines like the MAGNATEST TCL and MAGNATEST D 3.623, which provide cutting-edge solutions for material separation.

Table of Contents

What is an Eddy Current Sorter Machine?

An Eddy Current Sorter Machine uses the principles of eddy currents to sort materials based on their conductivity and magnetic properties. This non-destructive testing technique involves applying a high-frequency magnetic field that induces eddy currents in conductive materials. In the process, the part being tested is subjected to an alternating magnetic field generated within the test sensor.

As the part is exposed to the magnetic field, eddy currents are induced by magnetic induction. Depending on the electrical conductivity and hysteresis characteristics of the material, a potential is transferred from the material to the receiver winding of the sensor. By analyzing the received signal, the system can evaluate various conductive materials, including ferromagnetic, austenitic, and non-ferromagnetic materials.

Key Advantages of Using an Eddy Current Sorter Machine

Eddy current sorter machines helps in testing of mass-produced components for differences in:

- Low-cost eddy current module for non-destructive material property testing

- Genuine magnetic induction testing using harmonic wave evaluation

- Test parameters can be varied in large ranges

- Very simple device operation with State-of-the-art software with intuitive user interface:

- Sorting of the test pieces into two groups „OK“ and „NOK“

- 100% control using non-destructive testing method

Applications of Eddy Current Sorter Machines

Eddy current sorter machines used in various industries such as automotives and aerospace in testing of mass-produced components for differences in:

- Identification, material differentiation or sorting

- Microstructure

- Strength

- Hardness

- Testing of geometric characteristics, such as:

- Shape accuracy

- Completeness of assembled parts (bearings, etc.)

- Machining state on all metallic series parts, e.g. hubs, steering system components, connecting rods, sintered carbide balls, chain links, profile shafts, shearing heads, fasteners, tulips etc.

The Role of Automatic Eddy Current Sorter Machines

Automatic Eddy Current Sorter Machines have transformed material sorting by increasing speed and improving reliability. These machines integrate seamlessly into production lines, offering continuous high-speed sorting without manual intervention.

With automatic systems, companies achieve:

- Higher Throughput: Sorting thousands of parts per minute.

- Lower Error Rates: Automated systems reduce human error and ensure accurate results.

- Scalability: Systems can be easily expanded to meet growing demand.

Foerster Instruments India Pvt Ltd is the India’s leading manufacturer/supplier of eddy current testing machines. We introduced Eddy Current Series Sorting Machine to inspect hardness and with/without heat-treatment. According to different parts, we are able to combine conveyor and slide track along with user-friendly interface and self developed software to fulfill customers’ requirements.

Key Features of the MAGNATEST TCL and MAGNATEST D 3.623

Two of the most innovative machines on the market are the MAGNATEST TCL and MAGNATEST D 3.623, produced by FOERSTER. These systems offer precision sorting for industries requiring high sensitivity.

- MAGNATEST TCL: This Eddy Current sorter provides fully automated, non-destructive testing with a broad frequency range of 4 Hz to 20 MHz, offering high accuracy and low interference.

- MAGNATEST D 3.623: Ideal for applications in aerospace and automotive industries, this machine focuses on detecting hardness and material discrepancies with high-intensity induction current and harmonic wave evaluation.

Conclusion

Eddy Current Sorter Machines have become a vital tool in industries that require high-precision sorting. Whether you’re involved in recycling, quality control, or material recovery, these systems offer benefits like faster processing, greater accuracy, and cost savings. Machines like the MAGNATEST TCL and MAGNATEST D 3.623 represent the cutting edge of Eddy Current Sorting Technology, enabling more efficient sorting in industrial environments.

For more details on how Eddy Current Sorters can enhance your production process, contact us to request a demo. represent the cutting edge of Eddy Current Sorting Technology, enabling more efficient sorting in industrial environments. For more details on how Eddy Current Sorters can enhance your production process, contact us to request a demo.