Automated phased-array ultrasonic testing in the production process

Phased-array ultrasonic testing makes hidden defects in bars visible

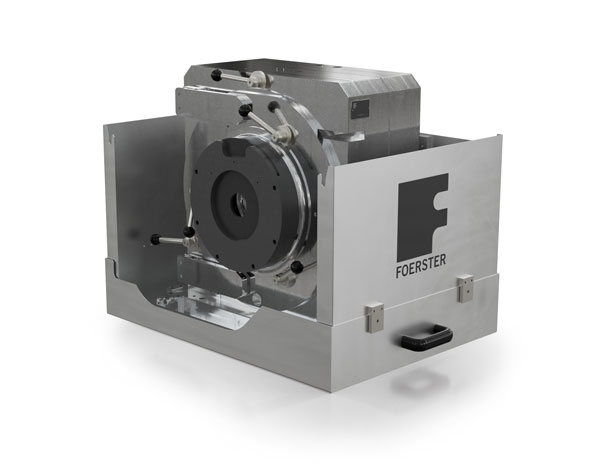

The BARPROOF is featuring precise non-destructive testing of your bars using phased-array ultrasound.

Well balanced probe sets with high sensitivity detecting smallest internal defects as well as surface and near-surface defects on bars with bright and hot-rolled surfaces.

A selection of different probe sets ensures maximum flexibility: the BARPROOF 140 covers a diameter range from 10 to 140 mm in just one housing size.

The consistent omission of rotating components significantly reduces the maintenance effort and wear part costs for the appliance.

Your advantages at a glance

- Single-source solution: We offer you the test instruments and test line for comprehensive and thorough inspection of bars with bright or hot-rolled surfaces, including service.

- Reproducible defect detection, high throughput: Detection of surface and internal defects as well as near-surface defects at test speeds of up to 2 m/s.

- Proven phased-array ultrasonic electronics: Includes industry-proven evaluation software and sensitive phased-array probes.

- Low maintenance: The absence of rotating components ensures minimal wear.

- Fast retooling when changing dimensions: Simplified device design and storable test settings shorten changeover times.

- FOERSTER Instrumentation Software: Optional integration for centralized display of test results.

Technical Data

| Diameter of bars: | from 10 mm to 140 mm |

| Types of defects: | ▪ Internal defects and near-surface defects such as inclusions and small, point-shaped defects ▪ Surface defects such as longitudinal over-rolling or cracks |

| Speed test: | up to 2 m/s |

| Standards: | ▪ AMS STD2145 ▪ EN 10308 ▪ and relevant requirements of the aerospace and automotive industries |

| Test material: | steel, aluminium, titanium |

| Surfaces: | bright and hot-rolled |